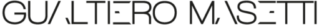

Alien

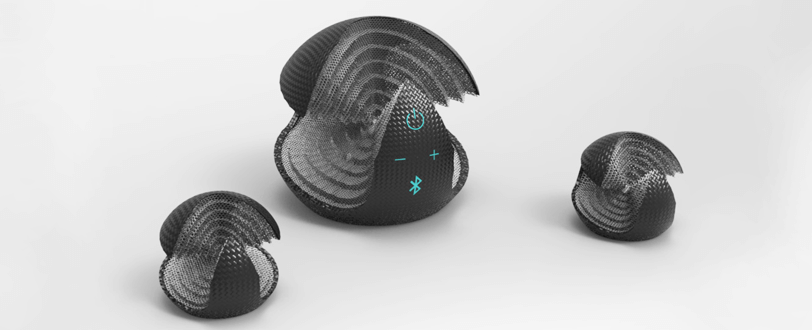

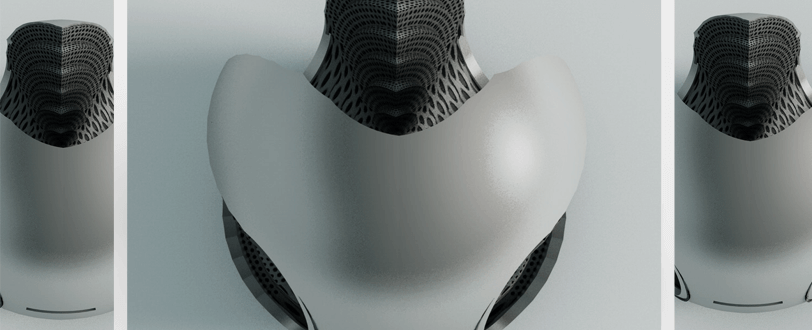

Starting from a pure solid, trough an hypotetical action of a milling cutter, the purpose of the project is to obtain a complex shape to turn into a real and marketable design product.

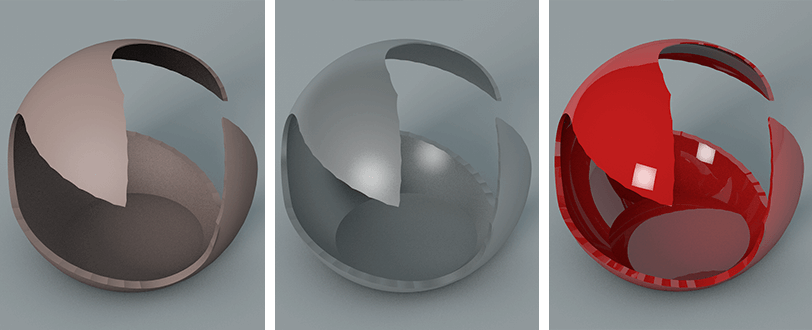

After testing several of the most common frills, in the field of stereotomic processing, I chose a “Steep Conic” tip, to work on a sphere. The machining acts on the 5 axis of the more advanced numerical control machine.

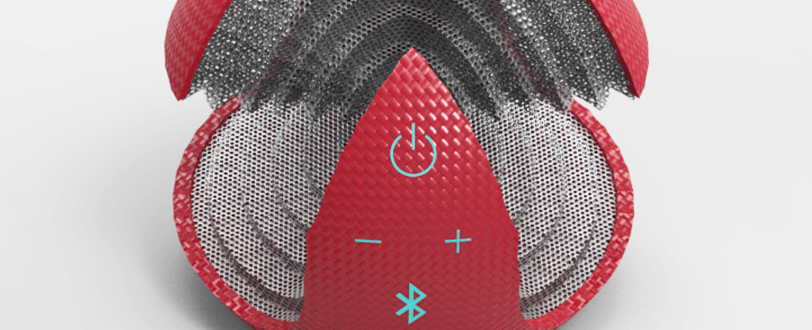

Subsequently the identification of the geometric shape, I tried to imagine what kind of design product could have that shape. The choice was an Hi-Fi system of last generation, but was necessary to transform an abstract form into a product for the mass production.

In the complete project (download at the page bottom), the analysis proceed about the materials and the industral processing to obtain a real object. For the shall was chosen ABS by injection moulding and for the grill Inox Steel 310 by pressing. The electric circuit arrangement plays a crucial role in the project, as well as the choice of the arrangement of the speakers inside of the shell.

Finally, it was presented the economic feasibility of the production with every cost details, from the finding of the raw material to the cost of the manpower.

University project.

Realisation of the project in concert with Jacopo Undari.

Thanks.